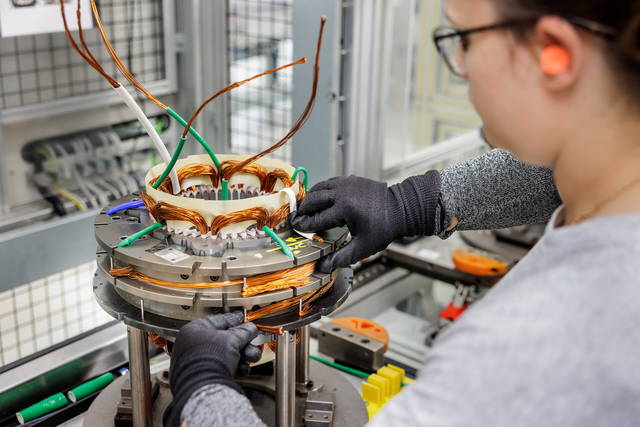

Compared to endothermic i Electric motorsBeing made up of only a few components (stator, rotor and casing) they are much simpler and, therefore, also more complex to increase their efficiency. In recent years, with the gradual spread of electric vehicles, manufacturers have begun research programs to improve them, focusing above all on their small size and light weight, to take full advantage of reducing spring masses.

there Renaultbenefiting from the cooperation of Valeo, a company specialized in components, announces the development of the new E7A electric motorWhich should be included in the French company’s electric cars initially From 2027. The electrical unit is currently in the prototyping stage and is characterized by the special compactness of its integrated structure, which makes it 30% smaller With the same power as the engines currently installed on the Mégane E-Tech Electric.

Furthermore it, Renault And Valeo worked on makingE7A More sustainable by reducing your carbon footprint by 30% thanks to a The rotor is free of rare earths (The rotor is the moving part of the electrical unit). This was achieved through coiled rotor geometry, rather than traditional permanent magnet technology. The result is a more compact and sustainable unit, with better efficiency and power of up to 200 kW (271 hp).

Renault will be responsible for engineering and supplying the rotor, while Valeo will supply the stator (stator), which can be relied upon to use Hairpin technology to assemble copper wires. to’E7Awhich for Renault It’s the electric motor third generationIt will also help reduce the battery charging time, as the voltage will go from 400 to 800 volts.

“Infuriatingly humble social media buff. Twitter advocate. Writer. Internet nerd.”